PowerUp2 Installation and Operation and Specifications Guide

Copyright information

This document contains proprietary information that is protected by copyright. No part of this document may be photocopied, reproduced, or translated to another language without the prior written consent of Idrive Inc. Copyright © 2020 Idrive Inc.

This product incorporates copyright protection technology. Use of this copyright protection technology must be authorized by Idrive Inc. Reverse engineering or disassembly is strictly prohibited. Information in this document is subject to change without notice.

Warnings

Please read the following carefully regarding proper use of the product and ensuring the user’s safety.

1. Use the idrive device only for its intended purpose.

2. Do not disassemble, attempt to repair, or alter the Idrive device. When malfunctions, errors, or other damage is found to be attributable to a user, said user may not be eligible for after sale service.

3. When cleaning the inside of a vehicle, do not spray water or any other cleaning product directly onto the Idrive device. It may cause damage, fire, or electric shock.

4. Keep the Idrive device away from chemicals or detergents as they may change the surface of the product or ruin internal components.

5. Do not insert any foreign objects into the Idrive device. Severe impact, shock, or other foreign matter may cause damage to the Idrive device.

6. Make sure the product is installed securely and do not expose the device to excessive shock. Do not move the device after installation.

7. Keep the product away from excessively humid or salty environments.

8. Use ONLY the supplied cable to connect the Idrive device to the power source, and only as directed in the manual. This product should be connected only to the power inside a vehicle. Any other power source is unacceptable and may cause malfunction or fire and may render the Idrive device ineligible for after sale service.

- The information contained in this technical manual may be accompanied by omissions, Idrive Inc., reserve the right to make further changes.

- Idrive Inc., does not authorize the use of the systems for medical purposes or the saving of human lives.

Idrive PowerUp2

DESCRIPTION

The PowerUp 2 is a high voltage power manager providing instant-on operation and high efficiency battery charging over a wide voltage range.

- Seamlessly used for 12Vdc to 24VDC embedded automotive systems; e.g. X2 & AI Camera Event Video Recording Systems.

An onboard buck-boost DC/DC controller operates with battery and/or system voltage above, below or equal to the input voltage.

- The PowerUp2 seamlessly manages power distribution between battery and converter outputs in response to load variations,

battery charge requirement and input power supply limitations.

- The module instant-on operation ensures system load power even with a fully discharged battery.

- Additional safety features include preconditioning for heavily discharged batteries and an integrated timer for termination

and protection.

- The module can provide constant-current/ constant-voltage charge algorithm

(CC/CV). Maximum converter and battery charge current are resistor controlled.

- Directional Male/Female connector and cables are provided for quick-connect to AI Camera and insertion of PowerUp2 quickly, without the need for additional wire connections

- Min. 35 Minute Power Back-up for AI at 350mA/h current consumptions

Technical Specs

FEATURES

- Wide Voltage Range: 8Vdc – 38Vdc, Up to 55Vdc

- Voltage Output 13.3Vdc – 15.6Vdc

- Maxim Current Output 1.65Adc

- Easy connect or disconnect from AI camera system

- Synchronous Buck-Boost DC/DC Controller

- LI-Po Charge and Protection Algorithms

- +/- 0.5% Float Voltage Accuracy

- +/- 0.5% Float Current Accuracy

- Instant-On for Heavily Discharged Batteries

- Ideal Diode Controller Provides Low Loss

- Power Path When Input Power is Limited

- Onboard Timer for protection and Termination

- Bad battery Detection with Auto-Reset

- NTC Input for Temperature Qualified Charging

- Binary Coded Status LEDs

- Battery Used Li-Po 500 mA, 14.8Vdc

- Min. 35 Minute Power Back-up for AI at 350mA/h current consumptions

ABSOLUTE MAXIMUM RATINGS

Maxim input voltage range | 55Vdc

Maxim input voltage operating range | +8 - +38Vdc

Automotive TVS for load dump protection (LDP01-42AY) | +42Vdc

Reverse polarity protection | yes (50Vdc)

Maximum operate sink current 2.5Adc

PTC overcurrent protection | 2.5Adc(25°C)

Maximum input voltage for all signals input | +/-65Vdc

Maximum input operating voltage for all signal input | +55Vdc /-0.6Vdc

LEDs and Status Test Button

The PowerUp2 contains 2 LEDs (ED1 red, ED2 green) that provide charger status and signals fault conditions

status. These LEDs binary coded signals:

- Battery charging

- Standby or shutdown modes

- Battery temperature fault

- Bad battery fault (unfulfilled preconditions)

Also, the system contains another bicolor led (ED3 red and green) that provide actual functional mode:

- Powered by VBAT GREEN

- Powered by internal VBAT1 RED

Vehicle Input-Power Side

Status, State LEDs and Charging Conditions

| Power LEFT LED | Power RIGHT LED | CHARGING CONDITION |

|---|---|---|

| LED OFF | LED OFF | Not charging–Standby |

| LED OFF | LED ON RED | Battery Fault |

| LED ON GREEN | LED OFF | Charging Cycle OK; Trickle Charging |

| LED ON GREEN | LED ON RED | Battery Thermal Sensor Shutdown |

Camera Side LED and Test Button

| Operation Mode | Output LED | OUTPUT CONDITION | Fault Troubleshooting |

|---|---|---|---|

| Powered by Vehicle Battery | GREEN | VBAT>/= 12Vdc & VOUT>/=12.5Vdc only,

else GREEN OFF |

Operating Properly |

| Powered by Internal Battery | RED | RED if current source minimum light 80, full light 400mA on VOUT only.

The led intensity variation is directly proportional with current consumption of camera if current consumption is less of 80mA, then RED LED is off |

Check Vehicle Input Voltage

Verify vehicle side of PowerUp2 - Red wire "Vehicle Battery" and Black wire "Vehicle Ground" to be =/>12Vdc or 24Vdc |

| Press/Hold Test Button | GREEN | Power connection OK,

VOUT is>than 12Vdc |

Operating Properly |

| Press/Hold Test Button | LED OFF | Input Power Failure

- PowerUp2 battery depleted |

Check Vehicle Input Voltage

- Red wire "Vehicle Battery" - Black wire "Vehicle Ground" to be =/>12Vdc or 24Vdc |

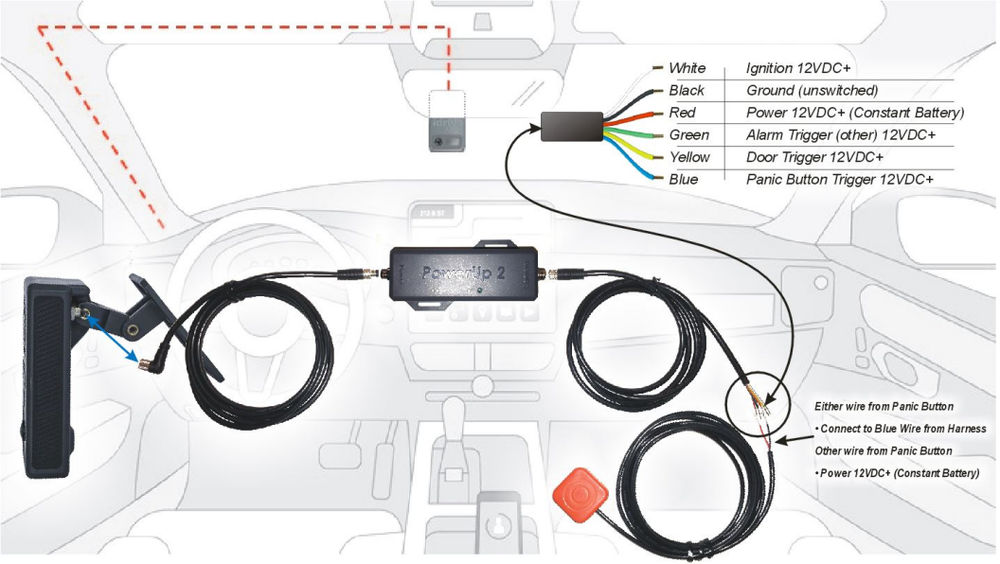

Wire Connections

Attach wires to the follow sources in vehicle as shown below:

Required Connections

There are 3 required connections for the Idrive device to function properly.

- Connect the BLACK WIRE to battery negative or to a clean, metal vehicle GROUND.

- The RED power wire must be connected through the supplied fuse to a continuous 12VDC+ power source. This power source should never be cut off.

- It may be necessary to make a direct battery connection if your vehicle has a battery cut off or does not supply non-interrupted 12VDC+

- The WHITE ignition wire must be connected to a 12VDC+ power source that is ignition switched. This wire tells the camera to boot up or to enter transfer mode to download events.

- NOTE: Many vehicles trick you to thinking you have connected to an Ignition Wire, but after ignition off might not drop to 0VDC until the driver door opens and closes

- Avoid any of these ignition connections that are electronically delayed or conditionally switched with the driver's door

Optional Connections

There are 3 optional wire connections that will trigger an event on the Idrive device. The description of the usage shown is suggested however each wire may be connected to the trigger point of your choice so long as electrical parameters are met.

If you choose not to use the optional wires, verify that they are secured properly in order to prevent shorting.

- Connect the BLUE wire from the Camera to the Idrive Supplied Wired Panic Button (or trigger method of your choice). This wire requires a MOMENTARY 12V RISING edge level transition pulse of at least 50ms duration.

- Connect the GREEN wire to an Alarm circuit (or trigger method of your choice). This wire requires a 0V to 12V RISING edge level transition pulse of at least 50ms duration

- Connect the YELLOW wire to a Door circuit (or trigger method of your choice). This wire requires a constant 12VDC+ and triggers with a FALLING edge level transition pulse of at least 50ms duration

Test Cable Connections

IMPORTANT! Use a voltmeter to verify the proper connection of each wire prior to plugging into the Idrive device.

Plug the Circular Power Connector into the camera and screw it finger tight

- NOTES:

- The Circular Power Connector is keyed and will only insert into the camera exiting with the cable oriented upward

- Vehicle power above is stated as 12VDC+, and can be wired to a 24VDC+ vehicle electrical system

- IMPORTANT

- if you are using 12VDC+ for the RED Power Wire, make sure you are using 12VDC+ for the WHITE Ignition wire

- Likewise, if you are using 24VDC+ for the RED Power Wire, make sure you are using 24VDC+ for the WHITE Ignition wire

- Maintain similar voltage (12 or 24VDC+ respectfully) for Blue, Green and Yellow wires (if used)

- IMPORTANT

- NOTES:

Electrical specifications

The below specifications are assuming an Idrive PowerUp2 is being used in circuit with the Idrive Camera

| PowerUp2 Specifications | |

|---|---|

| Input | 12-24 VDC Vehicles, Nominal Charging: 14.8 VDC for 12VDC, To Prevent Discharge

12-24 VDC Vehicles, Nominal Charging: 28.8 VDC for 24VDC, To Prevent Discharge |

| Output | LiPo (Lithium Polymer). Unlimited current consumption range +500mA -+700mA at 25 °C

Maximum current output (Battery powered) max. 1.67Adc for 60s paused 600s |

| Max Current | PowerUp is designed to support a single device. Maximum output voltage range (+12Vdc – +24Vdc) +15.6Vdc @ 1.67Adc. PowerUp2 is not designed to operate at Peak for prolonged periods of time and will decrease life |

| Back-Up Power | 12.5 VDC Nominal for connected Devices

X1P, X2, X2 V2 or AI Camera for minimum 20 minutes |

| LiPo Battery life | Min 1 year max 4 years (complete charge/discharge cycles reduces life expectancy) |

| Voltage Spike Protection | Maxim input voltage operating range +38Vdc

Automotive TVS for low dump protection (LDP01-42AY) +42Vdc |

| Operating Temperature | Relative humidity 90% without condensation

Operation temperature range -10C° - +55°C (NTC protection on) Storage temperature range -20C° - +70C° (without battery) Battery storage temperature -10C° - +55°C |

| Size and Weight | L: 5.5”, W: 3”, H: 1.75” |