Difference between revisions of "Manufacturing:X2 Device Manufacturing and Programming Process"

| Line 207: | Line 207: | ||

|- | |- | ||

|LED Plastic Lens | |LED Plastic Lens | ||

| + | |- | ||

| + | |X2 LED Board Assembly | ||

| + | |- | ||

| + | |X2 LED Ribbon Cable | ||

|- | |- | ||

|X2 Main Board Assembly | |X2 Main Board Assembly | ||

| Line 216: | Line 220: | ||

'''1.''' Snap the LED Lens into the Driver Side Case | '''1.''' Snap the LED Lens into the Driver Side Case | ||

| − | '''2.''' Snap the X2 Main board Assembly into the Driver Side Case as shown | + | ::- Ensure that the two LED indents are towards the bottom of the camera |

| + | |||

| + | ::- Clear LED lens is shown to enhance the view of indents | ||

| + | |||

| + | ::- Actual LED Lens is black/opaque as shown | ||

| + | |||

| + | '''2.''' Connect the LED Board to The Main Board with the Ribbon Cable | ||

| + | |||

| + | ::- Slide cable into the connectors with the contacts up as shown | ||

| + | |||

| + | ::- Slide the brown tabs at the sides of the connector to secure cable in place. | ||

| + | |||

| + | '''3.''' Snap the LED Board Assembly into the Driver Side Case as shown | ||

| + | |||

| + | '''4.''' Snap the X2 Main board Assembly into the Driver Side Case as shown | ||

[[File:x2drivercase2.jpg|left|250px|]][[File:x2drivercase1.jpg|right|800px|]] | [[File:x2drivercase2.jpg|left|250px|]][[File:x2drivercase1.jpg|right|800px|]] | ||

Revision as of 22:35, 15 December 2014

Copyright Information

This document contains proprietary information that is protected by copyright. No part of this document may be photocopied, reproduced, or translated to another language without the prior written consent of Idrive Inc.

About This Document

This document contains the information necessary to produce a Idrive Main board suitable for building of an Idrive X2 series camera. This includes all programming, testing, focus of lenses and bar code label.

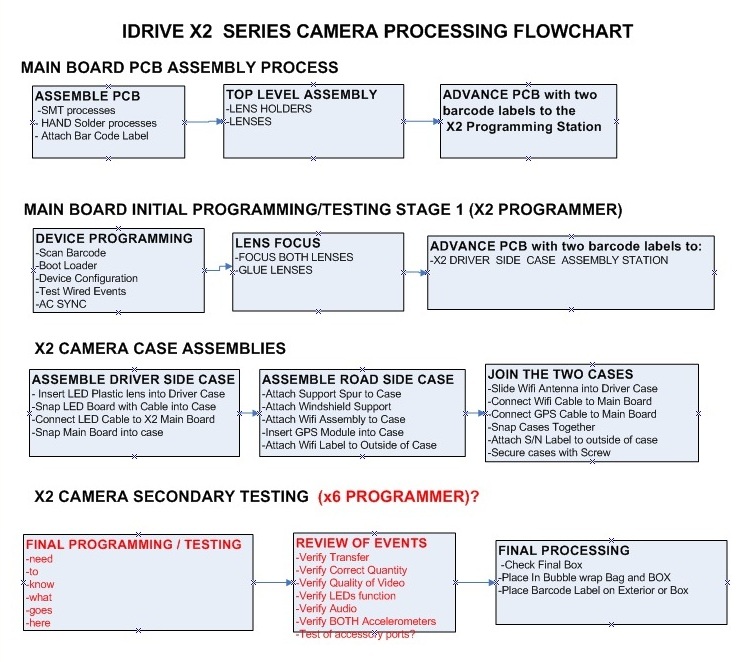

X2 Camera Processing Overview

X2 Main Board Assembly

Assemble PCB

| X2 Main Board PCB Assembly Materials |

|---|

| All components as listed in "Idrive X2 REV 1.1 Main Board" Bill of Materials |

| Pre-printed Bar Code Labels with Serial Number |

1. SMT Assembly steps - Use the supplied pick and place information supplied by Idrive Inc.

2. Manual Assembly Steps (Through Hole components etc)

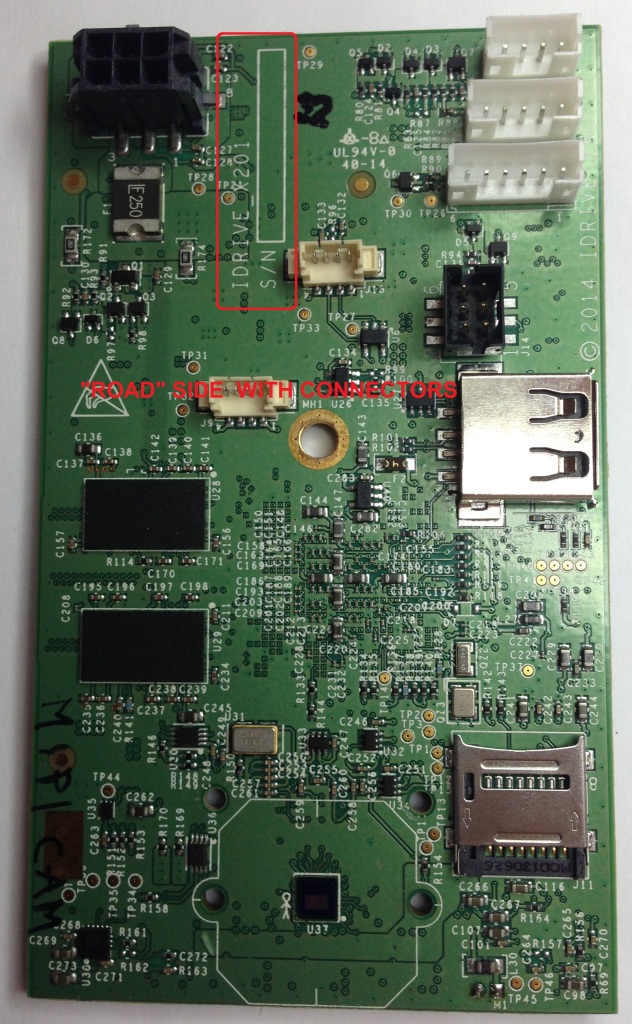

3. Place Barcode label in the S/N box on the PCB next to the Power Connector

Top Level X2 Main Board Assembly

| Top Level Main Board Assembly Materials |

|---|

| 4GB Pre-Programmed Micro SD card (Contains OS for camera) |

| 8GB Micro SD card (No pre-programming, used for event storage) |

| 2 Lens Holders (11mm Height) |

| 4 Lens Holder screws (2 for ech lens holder) |

| DSL-218A Lens for Road side of the camera (side of the PCB with the power connector) (the lens for the Road Side of the camera is different from the Driver side of the camera) |

| DSL-180C Lens for Driver Side of the camera (side of the PCB with the Processor on it) (the lens for the Driver Side camera is different from the Road Side of the camera) |

| Bar code Labels with Serial number |

1. Insert the Pre-programmed 4GB SD card into Complete this. as shown in #1 below

2. Insert the 8GB SD card into Complete this. as shown in #2 below

3. Mount of the two Lens Holders to the board as shown in #3 below

4. Inserting the proper lens in the correct side in the Lens Holders as shown in #4 below (Lenses are glued after programming and focus)

5. Advance the Top Level X2 Main Board PCB assembly to the X2 Programming Station

File:X2-driver side top assy.jpg File:X2-road side top assy.jpg

X2 Main Board Initial Programming

| Idrive X2 Programming & Lens Focus Materials |

|---|

| Idrive X2 Programming Station |

| Idrive Top Level X2 Main Board Assembly |

| Lens focus targets |

| Super Glue (for fixing lenses) (Loctite Control, Extra Time or equivalent) |

Initialize Programming Station

New X2 programmer picture here

X2 Programming Station Initialization

Setup X2 Main Board

1. Place the Idrive X2 Main board in to the Device holding Fixture.

2. Connect the Power cable between the Idrive X2 Main Board and the Programming Fixture.

3. Connect the ? cable between the Idrive X2 Main Board and the Programming Fixture.

4.

New Pictures of the X2 here

File:X2dutfront.jpg File:X2dutback.jpg

<br\><br\>

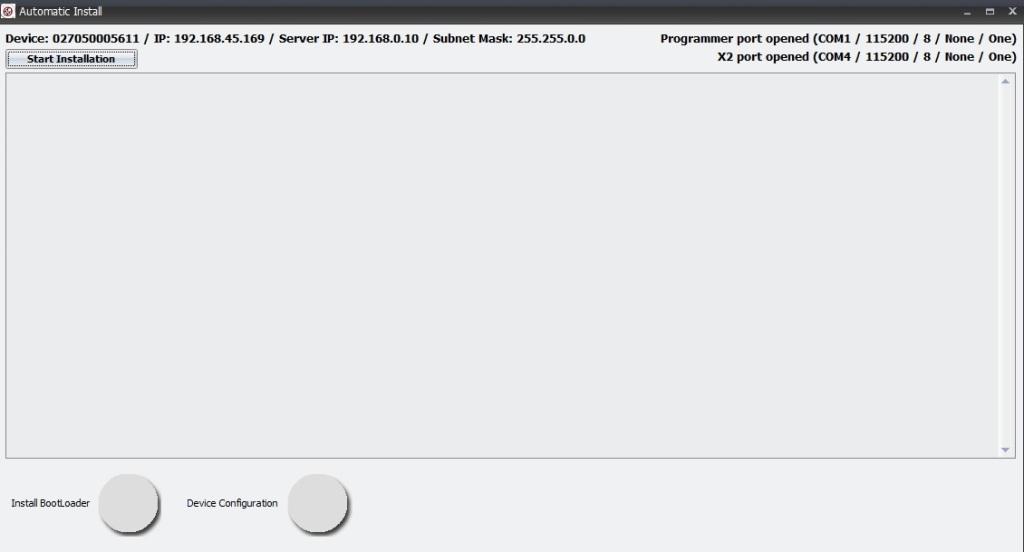

Automatic Install

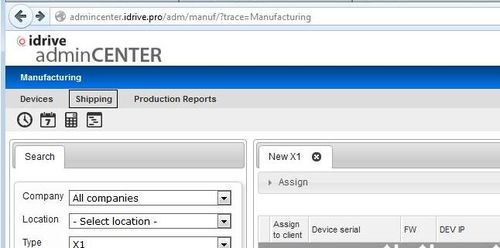

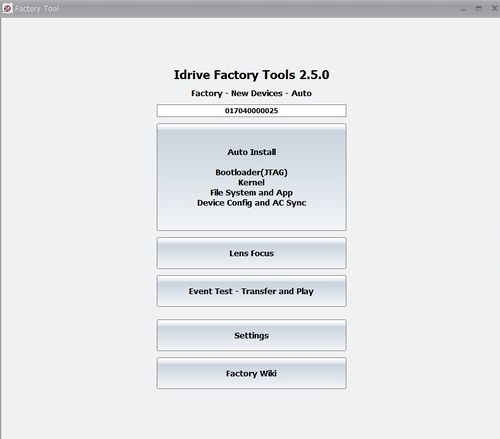

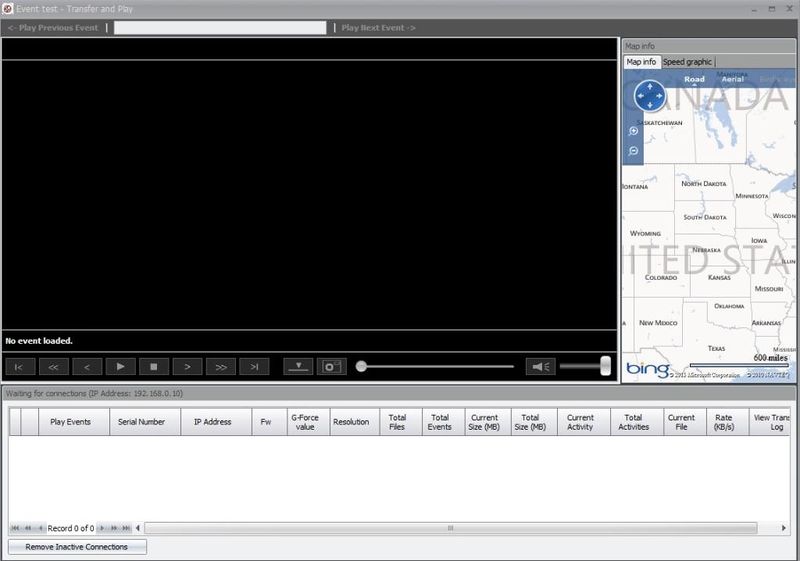

1. Click on the Factory-New Devices-Auto button to open The Automatic Install window

2. Scan the Bar Code label with the serial number (if no bar code scanner is available type the serial number from the bar code label into the serial number input field in the Idrive Factory Tools Application)

3. Click on the Auto Install Button and the Automatic Install window will open

4.Click on Start Installation Button

- The program will automatically step through the programming sequence and report status of each step.

- Installing Boot Loader

- Configuring Device

- Contacts Admin Center to get settings for the device

- Tests Door Wire Event

- Tests Panic Wire Event

- Tests Alarm Wire Event

- Tests GPS External Interface

- Tests Accessory Ports

- If any of these steps fail the program will stop and give an error. If all steps are successful the program will enter into Lens Focus Mode.

Lens Focusing

1. Select "Inside Camera" Tab and Focus the Driver Side Lens(DSL-180C) (the same side as the Processor). The focal length for the inside camera should be ~1.5 meters

2. Select "Outside camera" Tab and Focus the Road Side Lens (DSL-218A) (the same side as Power Connector). The Focal Length for the outside camera should be as far as possible

3. Once focused fix the each lens with a drop of super glue.

4. Verify that the lenses can not move.

5. Select "Both cameras" Tab and Verify the lenses are focused.

6. If images are focused and clear click on the "Lens Focus OK" button and the focus mode will close. If the image is not clear for some reason click on the "Lens Focus Not OK" the focus mode will exit so corrective action can be taken

7. Remove the assembly from the test fixture and Test the lenses after several minutes to ensure they have taken the glue and cannot be moved

8. Advance the Main Board Assembly to the Driver Side Case Assembly Station.

X2 Camera Top Level Assembly and Test

Driver Side Case Assembly

| X2 Drive Side Case Materials |

|---|

| Driver Side Plastic Case |

| LED Plastic Lens |

| X2 LED Board Assembly |

| X2 LED Ribbon Cable |

| X2 Main Board Assembly |

1. Snap the LED Lens into the Driver Side Case

- - Ensure that the two LED indents are towards the bottom of the camera

- - Clear LED lens is shown to enhance the view of indents

- - Actual LED Lens is black/opaque as shown

2. Connect the LED Board to The Main Board with the Ribbon Cable

- - Slide cable into the connectors with the contacts up as shown

- - Slide the brown tabs at the sides of the connector to secure cable in place.

3. Snap the LED Board Assembly into the Driver Side Case as shown

4. Snap the X2 Main board Assembly into the Driver Side Case as shown

Road Side Case Assembly

| X2 Road Side Case Materials |

|---|

| 1 |

| 2 |

| 3 |

| 4 |

Full Camera Assembly

| X2 Full Camera Materials |

|---|

| Driver Side Case Assembly |

| Road Side Case Assembly |

| Bar Code Label with Serial Number |

| Case Screw |

Final Testing

| Stuff |

|---|

| 1 |

| 2 |

| 3 |

| 4 |

Sub Assembly Processing

GPS

WiFi

LED Board

Plastic Parts

SD Card Preparation

The SD cards could be formatted EXT4 during configuration OR NOT, this option is available under settings . However, this is a quick format, it will take less than 1min for 64GB card. Usually 64GB cards are coming formatted ExFAT which is not supported by Linux so at least in this case we need this option but I will suggest to use EXT4 for all storage cards(8GB-64Gb) is more safe – FAT can be easily corrupt. Also there is an open source Windows driver for ext3/4 that can be used to read these cards: http://www.ext2fsd.com/

Mark Stopped Here

Top Level Camera Assembly

Final X1 Series Camera Assembly

| Idrive X2 Top Level Camera Materials |

|---|

| Idrive X2 Main Board Assembly (Programmed, lenses focused and secured) |

| Wifi Assembly with Antenna |

| Idrive X2 IR LED Assembly with Cable |

| GPS Assembly with Cable |

| Idrive X2 Plastic case |

Device Testing Stage 2 (Wifi, GPS,IR LEDs Shock Event, Transfers)

Need all new programmer information

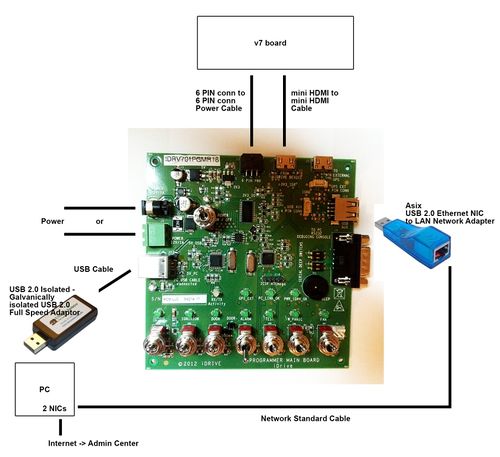

Note: The Idrive X2 programmer may also be used to perform this portion of the programming provided a wireless router is configured and connected to the system. For better throughput and to reduce the number of wireless networks in a factory environment it is recommended that the x6 Programmer be used. Because this document is intended to support production the x6 programmer process is shown here. See X2 programmer final programming process section in the Appendix for use of the V7 programmer for this portion of the process. -is this all still true?

<br\><br\>

Verify That the IR LEDS are working

Move this to camera assembly section. Show the new LED board and cable connections

1. Put your hand in front of the IR LEDs and verify that you can see the light reflecting in the Inside camera view.

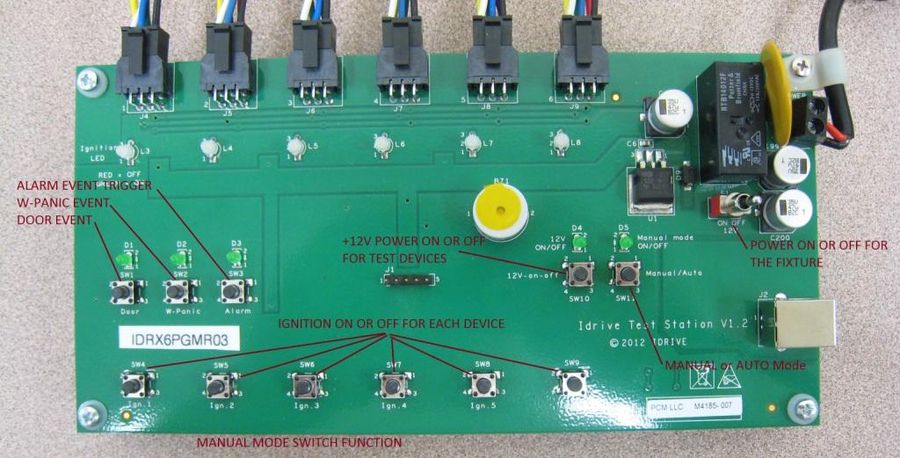

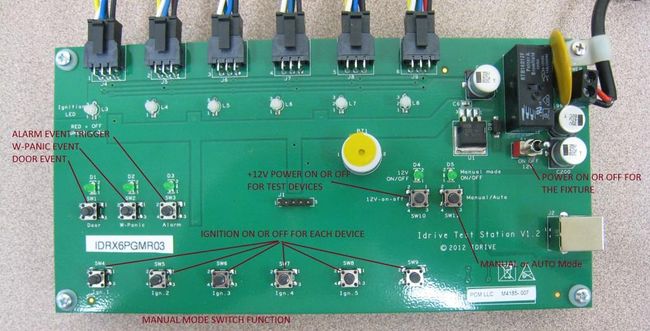

Stage 2 Automated Testing Process with x6 Programmer

Still applicable?

1. Initialize x6 programming station

x6 Final Test Station Initialization

2. Connect up to 6 cameras into the x6 programmer using the 6 pin power cables

3. Turn on the power switch of the x6 programmer (applies power to the programmer)

4. Press the "12 Volt On/Off" Button on the x6 programmer (applies +12volts to the Devices)

5. Press any one of the Ignition On buttons (Turns the Ignition on for all of the Devices)

6. When the Device(s) have both lights green shake each camera to generate a shock event Monitor Bi-color LEDs to ensure correct function

7. While capturing the event place your hand in front of the inside lens to verify IR LED Function

7. When both LEDs return to green for all Devices press any one of the Ignition On buttons (Turns the Ignition Off for all of the Devices)

<br\><br\><br\><br\><br\><br\><br\><br\><br\><br\><br\><br\><br\><br\><br\>

- Events from the camera download to the Factory Tool and automatically show up in the connections list. When finished downloading the camera(s) will shut off.

8. Verify that each device contacted the test station. (If not there is a problem with the Wifi)

9. Each event should be shown in Green text (Red text indicates a failure). Green indicates the following tests passed:

- The Device has a valid serial number

- There was at least 1 event (Shock Event was created)

- GPS Module is working

9. Press "Play events" link for each event and review the events. Review events for:

- Focus and Image quality

- IRLED functioning

- Verify that the audio is working

10. Disconnect the power cable from the Camera(s)

11. Check the "Final Box" in AdminCenter to make the camera eligible for shipment. Advance the Camera to Shipping

<br\><br\>

Shipping and Device Assignment

Using the idrive admincenter to ship idrive devices from the factory.

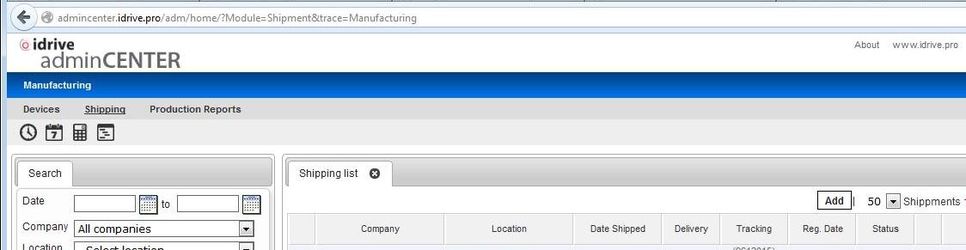

Login in with your user name and password to http://admincenter.idrive.pro

Click on shipping

Click on ADD to start the process

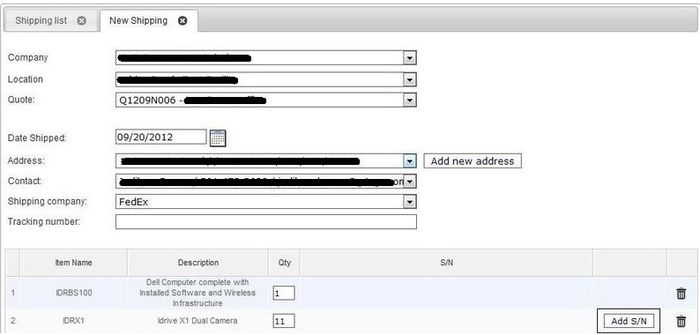

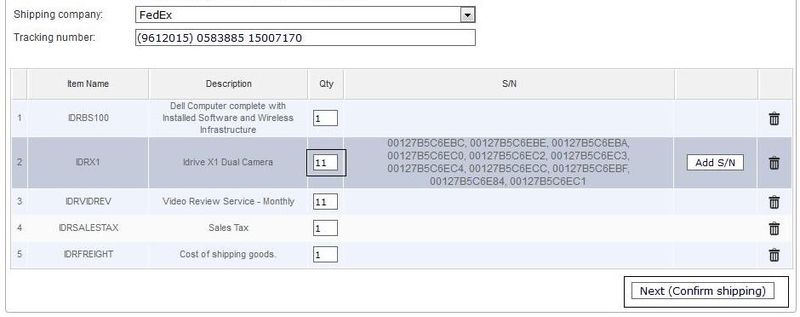

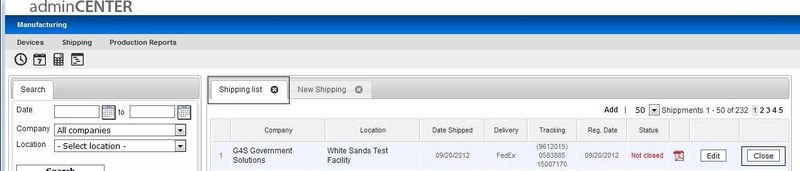

Use the Pull-down fields to select: Company, Location, Quote, Date, Address, Contact, Shipping Company (Tracking Number(s) can be entered later if it is not yet available). Click on "Add S/N" to open the form for device selection.

- We really need the scanner to do this to reduce the errors.

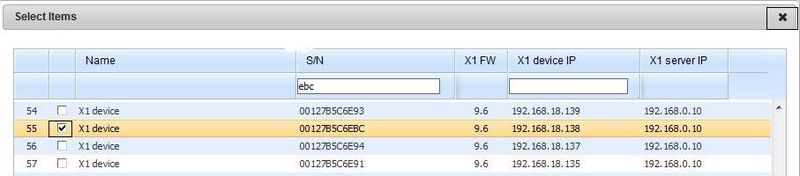

In the device selection form check the box next to the device(s) to be shipped. You can search the list by typing the last 3 characters into the "S/N" box which will highlight the device you are searching for. Once ALL of the devices are selected click on the "X" to close the window.

Verify the correct number of IDRX2 units (the other items ship from elsewhere) and Click "Next(Confirm shipping)"

- New Picture

After Confirmation a Shipping form will come up. This should be printed and included with the shipment of the devices to the customer.

- New Picture

Select the "Shipping List" Tab. If you need to add tracking information you must do it before closing out the shipment using the edit button. Select "Close" to assign the cameras to the customer as well as send the automated notification of the shipment to the people on the distribution list. The "Close" process will be performed by Idrive after our review of the shipment.

Done.

<br\><br\>

Appendix A - Idrive X2 Programming Station Documentation

Programming Station Components

- :* New Picture Rewrite entier section for new programmer

| X2 Programming Station Components |

|---|

| :* Computer with Monitor and speaker(s)(see requirements below) |

| :* Idrive V2 Programmer |

| Internet Connection |

| This |

| That |

| The Other thing |

| and |

| plus |

| this too |

| stuff |

| another item |

| Bar Code Scanner |

| Lens Focus Charts |

| :* New Picture SD Card (with firmware and filesystem files) |

| Micro SD card reader – primarily for RMA activity to recover events from the SD card |

<br\>

Computer Hardware Minimum Requirements and Setup

- Different requirements?

| Computer Hardware Minimum Requirements |

|---|

| Monitor (needs to support 1600X1200 screen resolution) |

| Speaker(s) |

| Windows XP or better, Windows 7 Professional recommended |

| 1GB RAM |

| 100 GB Hard Disk |

| 2 Network adaptors (NICs) |

Network Adapters LAN settings:

- Connection one for the Programming Fixture

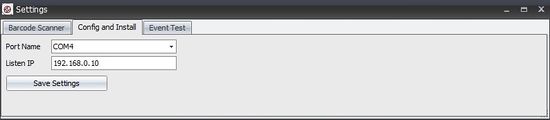

- - IP address: 192.168.0.10

- - Subnet Mask: 255.255.0.0

- - Default gateway: Blank

- - Connection two for local network with access to internet

- - DHCP or as required by location

<br\>

Computer Software Requirements

- Need requirements

- TeamViewer V9 (http://www.teamviewer.com ) - personal license. Install TeamViewer - during setup you need to choose the Personal license installation!

- OpenJTAG Driver for USB

- SDFormat tool the ( https://www.sdcard.org/downloads/formatter_4 ) DO NOT USE THE QUICK FORMAT Use the “Full(rewrite) option!

- Idrive Factory Tools 2.3.0

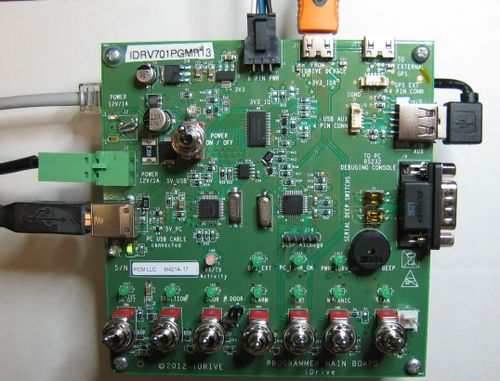

X2 Programmer Connections

New Picture

<br\><br\>

X2 Programmer Switches

New Picture

File:V7-Programmer-switches.jpg

<br\><br\>

X2 Programming Station Initialization

<br\>

1.Configure Switches on the X2 Programmer

New Picture

Ensure all switches are in the off position as shown.

Turn On the Power switch and leave the programmer on for the batch of boards.(you do not need to turn it off to program the next board)

Note: In auto programming mode only the Power Switch is used. The other the switch functions are controlled via software

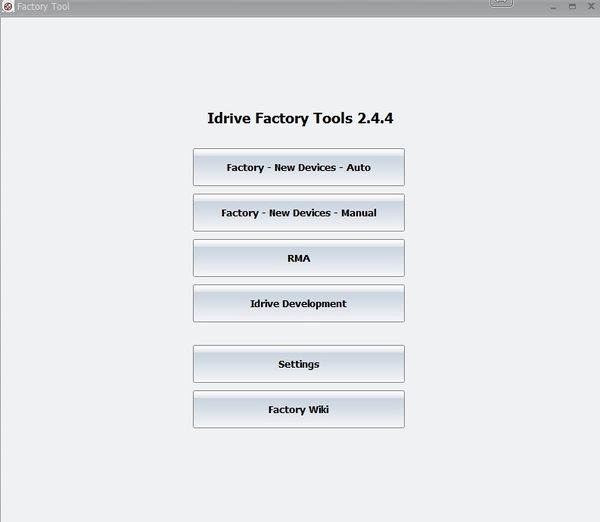

2. Launch the Idrive Factory Tools 2.0 Application

New pictures and process

- Factory-New Devices-Auto

- Select for Automatic programming of New Idrive X1 Devices (Most commonly used mode)

- Factory-New Devices- Manual

- Select for Manual Custom Programming of New Idrive X1 Devices

- RMA

- Select for RMA processing of Existing Idrive X1 Devices (Password protected)

- Idrive Development

- For internal Idrive Development use only (Password protected)

- SETTINGS

- Select to set Port number or non-standard IP addresses

- Factory Wiki

- Factory Manual on Admin Center

3. Configure Application Settings for the Programming Station

Same? Different

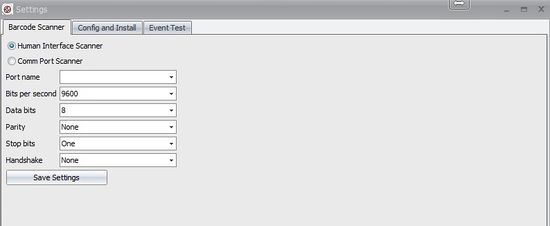

Click on Settings

Barcode Scanner Set the port number for the Barcode scanner. (Normally Human Interface Scanner)

(Port number can be checked in "Control Panel> System and Settings> Administrative Tools> Computer Management> Device Manager> Ports)

Config and Install Set the port number for the fixture.

(Port number can be checked in "Control Panel> System and Settings> Administrative Tools> Computer Management> Device Manager> Ports)

Event Test Set for non-standard IP addresses

4. Select Programming Mode (Normally Auto)

Same? Different?

- Click on Factory-New Devices-Auto

- Serial Number field

- 12 character serial number for the device to be programmed as read from the bar-code label on the Motherboard. The serial number can be typed in but usually it is filled in by the bar code scanner. After the field is populated press enter and the Auto Install Button will become active.

- Auto Install Button

- A valid serial number must be entered for the button to be active. When selected it will open the The Automatic Install window (see below)

- Lens Focus

- Reenter Focus mode for a device that previously failed this step.

- Event Test-Transfer and Play

- For Review of Events transferred from programmed X1 series board in the Final Programming Station

- Settings

- Set the Port number to look for the programming fixture

- Factory Wiki

- This document on the Idrive Admin Center

V7 programmer final programming process

Same? Different?

- 1. Open the Events test - Transfer and Play window in the Factory Tool

- 2. Power on the wireless router

- 3. Turn on the "Power On/Off" Switch on the V7 Programmer

- 4. Plug the 6 pin power cable into the camera (No HDMI Cable is used!)

- 5. Turn on The "Idrive On/Off" Switch on the V7 Programmer

- 6. Turn on the Ignition Switch and wait for the LEDs on the camera to turn Green/Green

- 7. Gently shake the camera to record a shock event (Left LED will be Red during recording)

- 8. When both LEDs on the camera are Green turn Off the Ignition Switch (Event will download to the Factory tool)

- 9. Review Event(s) and check for

- An event is present for each Camera

- Focus and Image quality

- Verify that the audio is working

- Verify there is GPS data for each event

<br\><br\>

Cable Diagrams

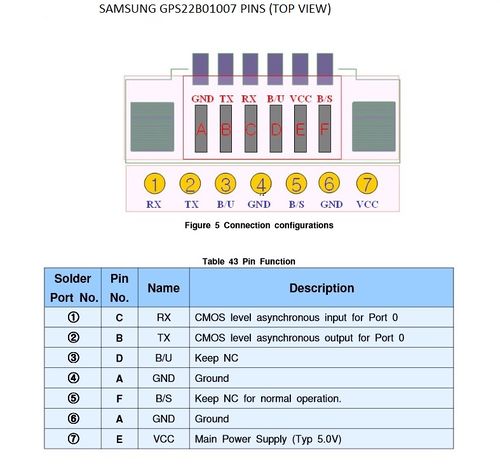

External GPS HDMI Cable

Same? Different?

| HDMI Connector pin | (Programmer Net Name) | GPS22B01007 Pin | SKM53 Pin |

|---|---|---|---|

| 1 | NC | NC | NC |

| 2 | NC | NC | NC |

| 3 | NC | NC | NC |

| 4 | IGND | A | GND |

| 5 | TXD1 | B | TXD |

| 6 | RXD1 | NC | NC |

| 7 | NC | NC | NC |

| 8 | NC | NC | NC |

| 9 | NC | NC | NC |

| 10 | NC | NC | NC |

| 11 | NC | NC | NC |

| 12 | NC | NC | NC |

| 13 | NC | NC | NC |

| 14 | NC | NC | NC |

| 15 | NC | NC | NC |

| 16 | NC | NC | NC |

| 17 | GPS_EXT_EN | E | VCC |

| 18 | VCC_GPS_EXT | E | VCC |

| 19 | NC | NC | NC |

Appendix B - Idrive x6 Programming Station Documentation

<br\>

Idrive x6 Final Programming Station Requirements

| Final Programming Station Components |

|---|

| Computer with Monitor and speaker(s)(see requirements below) |

| Idrive x6 Final Programmer |

| Internet Connection |

| USB Cable type B to type A max. 1.5m |

| Idrive Power Cables 6 PIN to 6 PIN |

| 2 Cat 5E Cable (internet connection, Wireless router) |

| Stabilized Power Supply 12V, 6A Minimum |

| Bar Code Scanner |

| Wireless router |

| SD card reader – primarily for RMA activity to recover events from the SD card |

<br\>

Computer Hardware Minimum Requirements and Setup

| Computer Hardware Minimum Requirements and Setup |

|---|

| Monitor (needs to support 1600X1200 screen resolution) |

| Speaker(s) |

| Windows XP or better, Windows 7 Professional recommended |

| 1GB RAM |

| 100 GB Hard Disk |

| 2 Network adaptors (NICs) |

Network Adapters LAN settings:

- Connection one for the Programming Fixture

- - IP address: 192.168.0.10

- - Subnet Mask: 255.255.0.0

- - Default gateway: Blank

- - Connection two for local network with access to internet

- - DHCP or as required by location

<br\>

Computer Software Requirements

- TeamViewer (http://www.teamviewer.com ) - personal license. Install TeamViewer - during setup you need to choose the Personal license installation!

- OpenJTAG Driver for USB

- Bar Code Scanner Software - need to identify

- SDFormat tool the ( http://www.sdcard.org/consumers/formatter_3/eula ) DO NOT USE THE QUICK FORMAT Use the “Full(rewrite) option!

- Idrive Factory Tools 2.2.0

x6 Final Programmer Connections

<br\><br\>

x6 Final Programmer Switches

<br\><br\><br\><br\>

x6 Final Test Station Initialization

1.Configure Switches on the x1 Programmer

Ensure the power switch is in the off position as shown.

2. Launch the Idrive Factory Tools 2.0 Application

This opens the transfer and Play window

Wireless router Setup

If a wireless router is used with the V7 programmer a small network hub is required to share the idrive programmer NIC on the computer.

- LAN IP address 192.168.0.1

- Network Mask 255.255.0.0

- Default Gateway Blank

- 5.8GHz band?

- Encryption?

- Same? Different? SSID bwifi

- No DHCP

- No DNS

- No WAN settings (not in use)

<br\>

Appendix C - Assembly Process Stations

<br\><br\>

Wifi Mechanical Subassembly

New Pictures

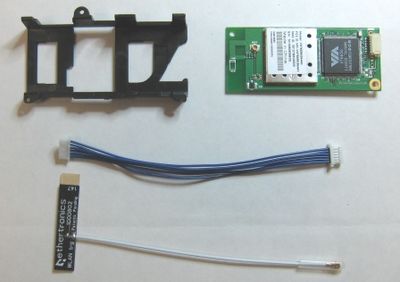

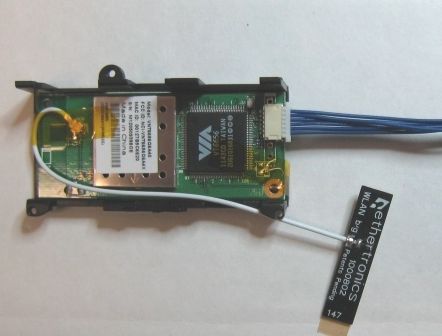

| Station 2 – “WiFi” Mechanical Subassembly Materials |

|---|

| 802.11agbn USB WiFi Module |

| WiFi cable |

| Antenna with cable |

| Low Static Hi-Temp Kapton Polyimide Film Tape 2.7 Mil, 3/8" |

| Wifi Plastic Carrier Lid |

| Double sided Tape for Antenna (Specify Type) |

<br\><br\><br\><br\><br\><br\>

New Pictures

1. Connect the WiFi Cable and Antenna Cable to WiFi module. Antenna Cable must be attached to the "MAIN" connector.

<br\><br\><br\><br\><br\><br\><br\><br\>

New Pictures

2. Place the Wifi and antenna into the Wifi Plastic Carrier and route the antenna cable as shown. Apply two pieces of Kapton tape to secure the wifi module to the plastic wifi carrier.

Note: The tape should never touch any portion of the PCB or circuitry. One piece must attach to the metal can with the sticker on it and cross over the antenna connection and touch nothing but plastic on the other side as shown. The second piece of tape should touch only the top of the chips and wrap around to the other side and touch only plastic as shown. This care must be taken so as not to interfere with the wifi performance!

<br\><br\><br\><br\><br\><br\><br\><br\><br\><br\><br\><br\><br\><br\>

3. Advance the Finished Wifi assembly to the Final Camera Assembly Station. Ensure the Serial Number label that came with the Wifi Module stays with the correct Wifi Assembly for the outside of the camera case.

<br\><br\>

X2 Road Case Mechanical Subassembly

New Picture without half brackets etc

| Station 3 – “Road Case” Mechanical Subassembly Materials |

|---|

| Idrive Road Side Case |

| Idrive Base Support - new style? |

| Idrive Half Bracket Screw Side - obsolete in X2? |

| Idrive Half Bracket Nut Side - obsolete in X2? |

| M4 Nut (2x) |

| N4 Flat washer (2x) |

| M4x25 screw (2x) |

| 3M very high bond double adhesive tape, 100C temp. resistant, 48mm width (for windshield mounting) |

| Retainer and Retainer Lid (pin in the middle of the support arms)- obsolete? |

Need the new process and pictures for plastics

1. Stick the 3M double sided tape on the flat surface of the Bracket to cover the entire surface area. Trim the edges of the tape with a scalpel.

2. Attach the two Half Brackets with the Retainer and Retainer Lid. Press the retainer pins together to fully seat them.

3. Attach the mated Brackets to the Road Case using a screw (M4x25), one M4 nut and one N4 washer.

4. Attach the support on the other end of the brackets as shown in the picture.

New Picture

<br\><br\>

X2 Road Case Mechanical Subassembly

New Picture without half brackets etc

| Station 3 – “Road Case” Mechanical Subassembly Materials |

|---|

| Idrive Driver Side Case |

| X2 IR LED Board assembly |

| X2 IR LED Ribbon Cable |

Need the new process and pictures for IR LED assebly

1. first

2. second

3. third

4. done

New Picture of driver side case with IR Assembly

Final X1 Series Camera Assembly

Need new Picture(s)with the new board

| Station 5 – “Final Assembly” Mechanical assy |

|---|

| GPS Assembly |

| Wi-Fi Assembly(With label for case) |

| Idrive Road Case Assembly |

| Low Static Hi-Temp Kapton Polyimide Film Tape 2.7 Mil, 3/8" |

| Idrive X1 PCB –pre-programmed PCB with Focused Lenses |

| Idrive Driver Side Case with IR LED board |

| M3x18 screw |

| 1 Label with bar coded serial number for camera case |

1. Place the Wifi assembly into the Road Case Assembly and align it with the 3 pins molded into the case. Route the Antenna Cable as shown and attach it to the case with the double sided tape. Secure the Wifi carrier to the case with a piece of Kapton Tape to prevent movement

New picture

2. Connect the WiFi module to the main board (Idrive X2 PCB)

New Picture

4. Place the Main Board into The Road Case. First insert the end of the board closest to the lenses and then click in the top. Use tweezers to deflect the top tab so that excessive force is not needed to seat the board. Ensure that the Wifi cable does not obstruct the USB connector opening or the lens.

New Picture

5. Place the second Bar Code Label (Serial Number) on the back of the case (make sure that the label for the case matches the label on the SD Card Connector).Need correct Picture Do we need the Wifi Label on here too for FCC etc?

6. Insert the GPS Module into the Road Case and connect the cable to the Main Board. Ensure that the cable is not pinched between the Black Ceramic Antenna and the Plastic case. This can cut and wear out the wires!

New Picture

7. Connect the ribbon cable from the IR LED board

8. Close the case starting with the top hooks.When the case is properly closed there should be no gap in the seam between halves of the case.

8. Fix the case with the central screw in the back.

<br\><br\>

Final Inspection and Packing

Final Inspection:

1. The correct placement of the adhesive tape on the Mounting Base

2. The correctitude of the assembly

3. No spots, no scratches etc.

4. The existence of the Serial Number and Wifi label on the back of the case

Each Idrive X2 Kit requires one each of the following:

| IDR-KIT-X2-V-TBD |

|---|

| Completed Idrive X2 series Camera |

| Idrive X2 Power Cable harness Assembly |

| Idrive Wired Panic Button Assembly |

| Idrive Driver ID Assembly - is this true? |